UHMWPE wear resistant liners

Tel:86-13255346127

Whatsapp:86-15963368815

E-mail:allen@dzabosn.com

Address:

Lingcheng District, Dezhou, Shandong, China,253500

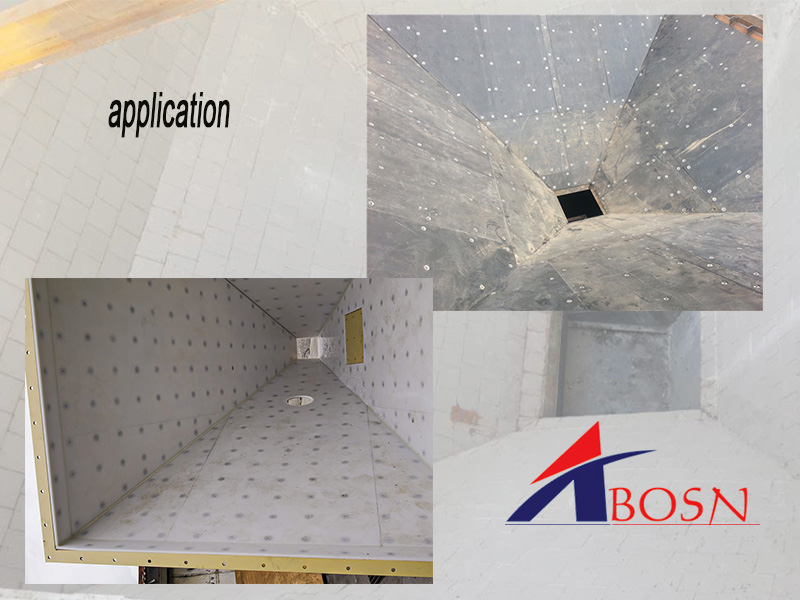

Coal Bunker Liner uhmwpe silo wear liner

-

◆ Product name:

Coal Bunker Liner uhmwpe silo wear liner

-

◆ Sort:

UHMWPE wear resistant liners

-

◆ Num:

SN1635385566

Precautions when using coal bunker lining:

1. For the first use, after the silo materials are stored to two-thirds of the entire silo capacity, discharge the materials.

2. During operation, always keep the stack of materials in the silo at the point where the materials enter the silo, and always keep the storage volume of the materials in the silo at more than one-half of the entire silo capacity.

3. It is strictly forbidden for materials to directly impact the liner.

4. The hardness particles of various materials are different. Do not change the materials and flow at will. If you need to change it, it shall not be greater than 12% of the original design capacity. Changing the materials or flow at will will affect the service life of the liner.

5. The ambient temperature for use should generally not be greater than 100 ℃.

6. Do not use external force to damage its structure and loose fasteners at will.

7. The static time of materials in the warehouse should not exceed 36 hours (please do not stay in the warehouse for viscous materials to prevent agglomeration). Materials with a water content of less than 4% can appropriately extend the static time.

8. When the temperature is low, please pay attention to the static time of the material in the warehouse to avoid freezing.

|

Property |

Value |

|

Density |

0.94~0.98 g/cm³ |

|

Working temperature |

-269~85℃ |

|

Melting temperature |

130~160℃ |

|

Elongation break |

350% |

|

Tensile strength |

45.3MPa |

|

Rockwell hardness |

R57 |

|

Bending strength |

23MPa |

|

Compressive strength |

≥30 MPa |

|

Impact strength |

100~160KJ/m³ |

|

Charpy notched impact strength |

≥140 KJ/m² |

|

Ball indentation hardness |

≥40 N/mm² |

|

Heat conductivity |

0.14~0.16%(m/m) |

|

Water absorption |

≤0.01% |

Contact us

E-mail:fiona@dzabosn.com

Phone:+86 175 5341 8926

Whatsapp:+86 175 5341 8926