Anti-UV HDPE single colored sheet

Tel:86-13255346127

Whatsapp:86-15963368815

E-mail:allen@dzabosn.com

Address:

Lingcheng District, Dezhou, Shandong, China,253500

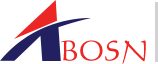

Blue Glossy Anti-UV Plastic HDPE Sheet

-

◆ Product name:

Blue Glossy Anti-UV Plastic HDPE Sheet

-

◆ Sort:

Anti-UV HDPE single colored sheet

-

◆ Num:

SN1636590933

1. High wear resistance: One of the eye-catching properties of polymer liners is that they have extremely high wear resistance, even the regular abrasiveness of many metal materials (such as carbon steel, stainless steel, bronze, etc.) is not as good as it. As the molecular weight of polyethylene increases, the material becomes more wear-resistant.

2. Extremely high impact resistance: The impact strength of UHMWPE is related to its molecular weight. When the molecular weight is less than 2 million, the impact strength increases as the molecular weight increases, reaching a peak at about 2 million. Later, if the molecular weight increases, the impact strength will decrease instead. This is because the molecular chain impedes its photocrystal function very often, so that there is a large amorphous region in the macromolecule, which can absorb greater impact energy. Even if UHMWPE has a low temperature of -40oC, it still has a very ridiculous impact resistance. Even at a temperature of -269oC in liquid gas, it can still maintain good impact resistance. This excellent low temperature characteristic makes the ultra high The application of molecular weight polyethylene is extended to the field of low temperature engineering.

3. Very low friction coefficient: UHMWPE is very wear-resistant, has low friction coefficient and good self-lubrication. It is an ideal bearing sleeve, slider, and lining material. Using ultra-high molecular weight polyethylene as the friction part of the equipment can not only increase the wear-resistant life, but also receive energy-saving effects.

4. Good chemical corrosion resistance: Ultra-high molecular weight polyethylene has good chemical corrosion resistance. Except for concentrated nitric acid and concentrated sulfuric acid, it will not be corroded in all lye and acid solutions, and can be exposed to temperature (80oC concentrated hydrochloric acid is used in <20% nitric acid, <75% sulfuric acid is also stable, it is also very stable to water and liquid washing.) However, UHMWPE is used in aromatic materials or halogenated materials The compound (especially at higher temperature) is very easy to swell, therefore, special attention should be paid to the application.

5. Very low water absorption: Ultra-high molecular weight polyethylene has a very low water absorption rate. It almost does not absorb water and does not swell in water, which is much smaller than nylon.

6. Thermal performance: According to the ASTM (load 4.6kg/cm2) method, the heat distortion temperature is 85oC. Under a small load, the use temperature can reach 90oC. Under special circumstances, it is allowed to be used at a higher temperature. , Since UHMWPE is a material with excellent toughness, its low resistance performance is also very good. It still has a certain degree of ductility at low temperatures of -269oC without signs of embrittlement. To

7. Electrical properties: UHMWPE has excellent electrical properties in a wide temperature range. Its volume resistance is 10-18CM, breakdown voltage is 50KV/mm, and dielectric constant is 2.3. In a wide temperature and frequency range, its electrical properties change very little. In the heat-resistant temperature range, it is very suitable for use as a structural material for electrical engineering and a material for paper mills.

8. Non-toxic UHMWPE is tasteless, non-toxic, odorless, non-corrosive, and has physiological cycling and physiological adaptability.

Product display

Contact us

E-mail:fiona@dzabosn.com

Phone:+86 175 5341 8926

Whatsapp:+86 175 5341 8926